Wednesday, November 24, 2021

Improving strength in a landing gear bulkhead

Tuesday, November 23, 2021

How to make a plug for Composite Amphibious Floats

Ever wanted to fly on water?

First of all, this is a work-in-process. The plug is not yet complete. In fact, as I write this, it is in storage, ready for next steps. That next step would be to finish the plug, and then use it to either make a mold or start making parts.

Secondly, this is just a pictorial journey.

As a brief overview, I created a design for a float in CAD, then exported into slice files for cutting in foam. They were stacked and shaped, then glued to a plywood bottom base. Fiberglass was applied for strengthening, also some aluminum rails.

And that is where the project sits now. It's in storage. :-/

Monday, November 22, 2021

Breaking the Landing Gear Bulkhead on my Chipper 2

Stupid Pilot Tricks...

I had just installed the new oil thermostat in my Chipper 2. I pulled the plane out of the hangar, eager for a break in the routine. (I was early in the process of installing shock absorbers on the plane.) It was a beautiful afternoon, the sky was blue, the grass was green, and the plane was gorgeous.

As usual, my UL350iS powered up without a hitch. My goal was simply to warm up the engine and check oil pressure & temps. The process of warming up was taking a long time (it was a little chilly) and I advanced power while keeping the brakes engaged. This went on for several minutes. I edged the power up a bit more. My brakes were having a hard time keeping the plane from creeping forward. I'd ease back on the power, hold the brakes a little tighter, and advance power again.

All of this was extremely poorly thought out.

After advancing power again, the plane started to list to the left and settle down to the ground, like it was kneeling. Realizing that a prop strike was imminent, I retarded throttle. The tip of the prop cut into the soft grass and dirt, carrying through several blades before all became silent.

I broke my plane.

I did not take a picture. I was flaming mad. My hangar mates swiftly emerged from a hangar backroom, having heard the commotion, and walked towards me as I got out of the kneeling airplane and looked at one gear leg bent backwards. I realized that I had twisted the gear attach bulkhead. (The gear leg was not hurt.)

Then I realized I had forgotten to re-install the trailing links, so I had just ripped my gear out because of my forgetfulness.

With the help of my friends, we rolled the wounded bird back into the hangar.

The inside of the cockpit looked like this:

And after several days of drilling out rivets, chopping out aluminum bulkhead, and cutting / pulling / fussing / fuming, the removed bits looked like this:

Over the course of the Thanksgiving holiday, I will be stepping you through what I have learned on how to repair this problem in my Chipper. I have also been using this opportunity to solve some other problems.

1) Improved bulkhead assembly for potentially higher gross weight

2) Shock absorber installation for potentially higher gross weight

3) Improvements in mounting techniques for bolts in honeycomb

4) Improvements in bonding techniques

5) General proof that this structure is repairable

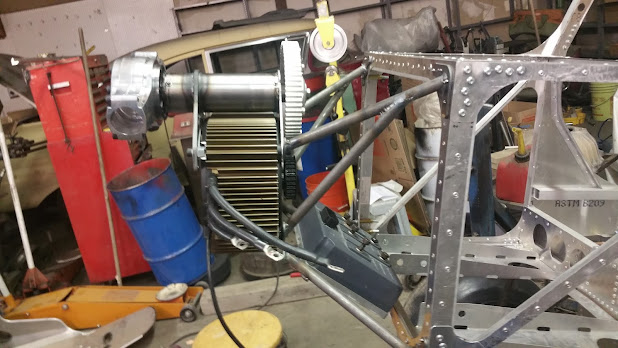

And as I head into the Thanksgiving break, things are much improved. Here's a photo of how things were looking earlier this afternoon.

Live & Learn.

Friday, October 29, 2021

Is Now the Time for Electric Ultralights?

The biggest use of ultralight aircraft is to enjoy flight. To that end, is now the right time for an electric ultralight aircraft? I've been there and done that and want to share my history with you.

My History with Electric Ultralights

I've designed and flown electric aircraft. I threw a lot of money into this one, which featured a carbon fiber fuselage and wing. It is called "SkyDock". I developed it with a gas engine as well.

A couple of years before that, I adapted an electric motor to a classic Belite ultralight.

- Ultralights are flown for fun; and electric flight is super fun!

- Electric motors are available with incredible value and excellent power;

- The best batteries ever are now available;

- U.S. ultralight law allows individuals to do this experimentation easily;

- Even a company or two (eg: Chip Erwin and Merlin) are publicly showing their work with electric ultralights.

- Electric flight in ultralights is proven by myself and others.

- Batteries can produce acceptable flight times for ultralight aviation.

- FAR 103 and Experimental rules allow it.

- Bonus: Electric motors are less expensive than gas motors. (Although offset by battery acquisition costs.)

- Electric flight has a unique sound signature, better and different than any gas motor. It's just the prop and the airframe, no combustion sounds!