Please note: James' blog has moved to a Wordpress site. To access it, please visit

http://jameswiebe.wordpress.com/. All posts have been transferred to the new site, and all new posts will only be accessible via Wordpress. Thank you for your interest!

This is a third in a series of article on how to build a Belite aluminum cabin.

The first in the series may be found

HERE.

The second in the series may be found

HERE.

Random reminder: All of the standard warnings and disclaimers apply. Flying a Part 103 Ultralight Aircraft may be dangerous or deadly. These aircraft are not certified under any FAA regulations. They are not built from certified aircraft materials. You are required to sign our standard liability release before we'll ship you a plane or a kit. You take full responsibility for your aircraft and its operation, per federal law, and per our liability release, no matter who built it. (Us, you, or someone else...)

Sigh... American liability... Now, onward.

****

The cabin in the Belite Ultralight Aircraft has several noteworthy, eyebrow raising features. For instance, I am very pleased with the number of storage / baggage compartments which I've been able to design into the plane.

Before we get started with today's construction, let's look at some photos which preview the results of your construction project!

|

| Belite Ultralight Aircraft Cabin Assembly, with teal blue Oracal |

|

| Three individual storage / baggage compartments, with solid aluminum bottom |

|

| Chart compartment, on left side of cabin |

***

Now, directly on to the construction. We'll pick up where we left off in the last installment.

Cut thin wall square tubing for the front seat cross box, and then cleco the two skins to that tubing.

|

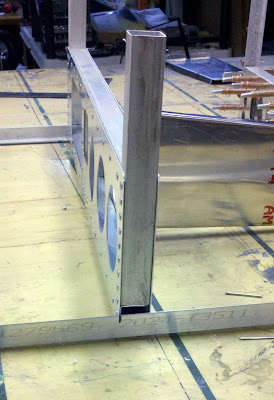

| Thinwall tubing for Front Seat Cross Box. Note one short center piece missing. |

You'll need to cut and fit the short tubing piece and cleco it in place as well. I'm sorry it missed the above picture, but it is in the next picture, below.

|

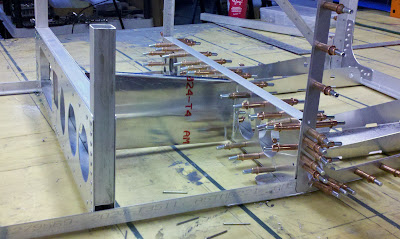

| Skins, clecoed to tubing for front seat cross box assembly. Short piece is clecoed inbetween. |

Now we'll work on the baggage divider for the front compartment.

|

| Baggage Compartment Divider |

There are three baggage dividers. Select the one for the front compartment, which looks like the photo, above.

|

| Front Baggage Divider, after bending tabs. |

After bending tabs in a box break, the divider will look like the above photo. The divider is then clecoed in place, and it will help to support the front seat cross box assembly.

|

| Front Baggage Divider, clecoed in place. |

|

| Front Baggage Divider, riveted in place. |

|

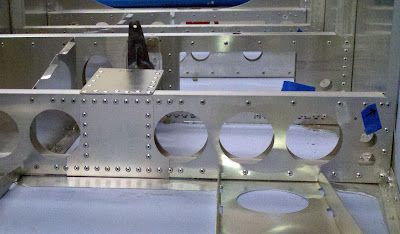

| Front Seat Cross Box, riveted together |

|

| Front Seat Cross Box, riveted together with quartering view |

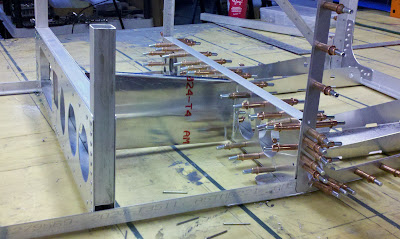

Then we proceed to the Middle Seat Cross Box.

|

| Middle Seat Cross Box, cleco assembly identical to Front Seat |

Now we need to make a notch in each longeron, immediately after the Front Seat Cross Box. Make a mark as shown below:

|

| Mark in longeron. |

|

| Cut notch in longeron. |

The notch will allow us to bend the longerons up, about 5 degrees. The actual angle is determined by the precut side skins, which are coming soon.

|

| Side skin being cut. |

|

| Side skin clamped onto side of cabin assembly. |

The bend in the side skin determines how high to bend up the longeron. A clamp in the above photo is holding the longeron against the side skin, so the angle is perfect. Note the clecos already holding the side skin as well.

|

| Closeup of overlapping star gusset. |

Note how everything overlaps. The top door side skin (not yet installed) will overlap into the same area and determine the final angle of the vertical longeron, and that is why its holes have not yet been drilled through.

|

| Even more clecoes in the side skin, while Lucky snoozes. |

One of our shop cats got in the photo. Our cats are named Second Chance and Lucky. Both are gorgeous and friendly.

|

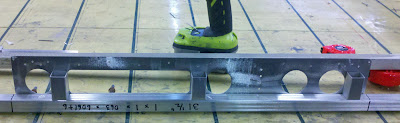

| Bottom Cross Lift Strut Tension Member and rear structural angle parts |

Cut the three parts as shown, above. The bottom Cross Lift Tension Member is 1x1x.063 6061T6. It is NOT thinwall tubing. At 6Gs of (hypothetical) lift, this piece is carrying around 5,000 pounds of tension. (And on paper, it's good for it.)

|

| Error in side skins |

When this production prototype was under construction, the side skins did not have a rear 1 x 1 notch. Yours should have a notch, but the longeron will still need to be cut out, so that they look like this:

|

| After notchout and longeron cut. |

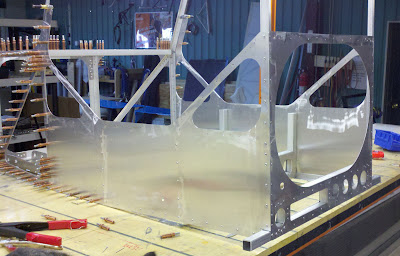

The cross member will form the base of the rear cabin. Construct the rear cabin cross box:

|

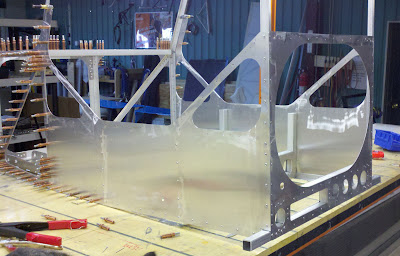

| Rear cabin construction begins. |

|

| Rear Cabin Cross Box with rear skin. |

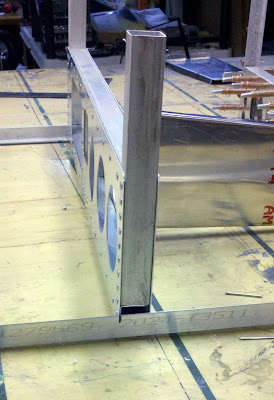

Add the thinwall tubing.

|

| Thinwall tubing for top of Rear Cabin Cross Box. |

|

| Thinwall tubing placed into Rear Cabin Cross Box. |

Now, it's time for some riveting. Note rivet sizes as always, based on the photos:

|

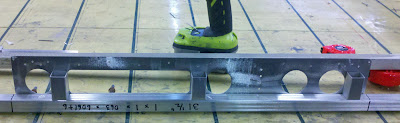

| Rivets on Cross Boxes. |

|

| More rivets hold side skins and cross boxes. WARNING: Extra rivets shown! |

The warning refers to a few extra rivets which have been placed, and which will have to be drilled out to attach Rear Fuselage Gussets.

The Cross Boxes must be aligned perfectly with the pre-drilled holes on the side skins. I failed to do this on one of the Cross Boxes in this production prototype, and you can see that the middle Cross Box is leaning towards the camera, perhaps by one degree, in the photo below:

|

| Mis-aligned Cross Box, (very slight). Don't make this mistake! |

|

| Lucky strikes another pose, with rear of cabin assembly |

|

| Another view of rear, this time with rivets drilled out and replaced with clecos. |

This is a good time to stop for the day. The Belite ultralight airplane cabin is beginning to look like a cabin!