Please note: James' blog has moved to a Wordpress site. To access it, please visit

http://jameswiebe.wordpress.com/. All posts have been transferred to the new site, and all new posts will only be accessible via Wordpress. Thank you for your interest!

I hope you had an awesome Christmas!

Shortly before Christmas, I had an amazing two hour flight in the Burgundy UltraCub. I flew out into the flint hills again, and made a video of most of the flight. I took lots of photos of sights along the way, including wind turbines near Beaumont, KS, and a friend's house out in the flint hills as well. I'll be posting an edited copy of that video soon; along with some of those photos.

When I returned to home base after that flight, the plane still had over a gallon of gas in the tank, and I've now accumulated 7.9 hours in the Burgundy UltraCub to date. I thoroughly enjoy the look and sound of the 1/2VW engine.

We will install a brand new cabin in the Burgundy UltraCub over the next 8 weeks, so that when it goes to Florida for Sun N Fun, it will be absolutely up to date with our current design. (The original cabin was hand built without the benefit of CNC placement of drill holes; lots of stuff didn't line up well; and some of the features in the final cabin design were missing; PLUS it had extra tubing and weight where some dimensions were screwed up...) So stay tuned on that...

***

Today I am posting Episode 4 of the ongoing saga of how to build a Belite cabin. The actual construction of this ultralight aircraft cabin goes very rapidly, and everything lines up, and it's just thrilling to build a structure which is so very light and very strong and very aesthetic all at the same time... and that is a lot of ANDS.

For links to earlier Episodes, just search "construction" in the search window of this blog. The search window is on the right side of the blog.

Some of the following construction jumps around a bit. I have two reasons for this:

a) It beats the boredom of just working on one area of the cabin.

b) It gave me something to do while waiting on our ShopBot to cut more CNC parts. You won't have this problem, as you'll have all the parts in front of you.

Let's cut two thin wall 1", 34 1/4" tubes.

|

| You'll need two thin wall 34 1/4 inch square aluminum tubes. |

And also a 23 7/8 inch tube of the same material:

|

| And a 23 7/8 inch tube |

The 23 7/8" tube clamps in place along the top of the rear gusset. The longer tubes rest on each side side skin. One side and the rear is visible in the following photo:

|

| Rear tube and side tube |

|

| Rear tube clecos |

|

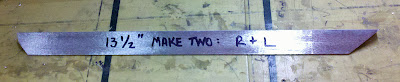

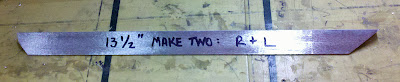

| Front Diagonal Supports |

|

| Front Diagonal Support clamped in place |

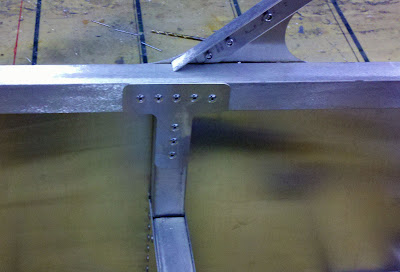

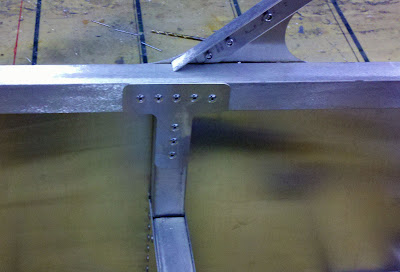

|

| Front Diagonal Support with rivet and clecos |

|

| Front Diagonal Support fully riveted |

In a similar manner, cut and fit two Rear Diagonal Support, then clamp and cleco in place.

|

| Front Cross Box rivets, from other side. |

Now, fit the Front Cabin Cross Tube Gussets. Yours are probably pre-notched, but I had to notch mine.

|

| Gussets for Front Cabin Cross Tube. |

Although the above photo only shows one gusset, the gusset is actually doubled (one on top of the other). It's time to pull some rivets:

|

| Gussets with rivets and clecos |

Now our focus shifts to installing four Side T Gussets, two on each side of the airplane.

|

| Side T Gussets clamped and clecoed. |

|

| Side T Gusset riveted in place. |

Please make sure you've placed clecos in the rear tube, as shown below:

|

| Clecos on rear tube |

Gussets need to be added on each Rear Diagonal Support. A bend is placed in each gusset prior to placement.

|

| Rear Gusset for Rear Diagonal Supports. |

|

| Another view of gusset for Rear Diagonal Support, clearly showing bend |

|

| Rivets on the gusset |

Ensure that rivets have been placed on the bottom of the rear fuselage.

|

| Rivets on bottom of rear fuselage. |