I was flying N3748, the very first Chipper 2, and I was in cruise, home-bound from a successful Sun-N-Fun in a stiff headwind. One moment, a very choppy but normal aircraft experience. The exact next moment, the propeller was dead-still, and had come to that dead-still position in just one or two revolutions of the crankshaft. It was the kind of violent engine stoppage that screams that all is not well, and that your 'full and undivided' attention needs to be on resolving the emergency of the moment. I looked down, as I scanned the area for a place for an immediate dead stick emergency landing.

I took some critique recently for editing and posting a YouTube video which was described as click-bait. This article is not that; I will tell you exactly what happened, how I responded, and what we found in the engine. I have witnesses who were there, and I have photos of the aftermath of the engine. I won't belabor this story; I've kept this as a short and easy read.

Sun-N-Fun, 2018

But the first order of business for this curious tale is to backup just a few days, to Sun-N-Fun, 2018. I was there with Chipper 2, and it was a success story. Chipper 2 N3748 performed without flaw, showing outstanding takeoff and landing capabilities.

To my delight, it even got the cover of General Aviation News. Describing the airplane as "Chipper in Paradise", it helped fuel good PR, sales, and momentum for Chipper Aerospace, my company.

Engine Changes

Chipper had started out as a two place aircraft project. I originally saw it as an airframe powered by a 60HP engine. To that end, I'd purchased a used Japanese HKS 700e engine, installed it on the plane, and discovered that the engine needed an overhaul. So Chipper never flew with 60HP.

After much consideration, I purchased a new Rotax 912UL, an 80HP engine, brand and spanking new. Everyone who flew it loved it. It did not disappoint at 80HP, and was bucking the trend that light sport aircraft needed to have 100HP engines. Hogwash; I showed them otherwise and proved it.

Yet there was that lust for power, for an improvement in ground roll, for an increased angle of climb. Without changing to yet another engine, the only way I could squeeze more performance out of my Rotax was to upgrade it using an aftermarket kit. When the engine had about 150 hours of use on it, I decided to purchase an engine upgrade from Edge Performance.

The kit was ordered and received. It was principally installed by a local A&P mechanic. I never touched anything; I'm not an engine guy.

The upgraded engine on N3748 was what I took and showed in Florida.

And its performance was fairly phenomenal. Here's video proof, which I took in-cockpit while taking off in front of a crowd at Sun-N-Fun:

The Flight Home

This is what I remember about the flight home. First of all, the wind, blowing on the nose of the airplane, making every effort to slow my progress. I tried low altitudes. That increased airspeed, at the expense of bitter, angry jostling of the airframe. I tried high altitudes. A smoother ride, at the expense of speed. For a long while, I was just a few hundred feet off the Alabama forests, with no landing options but with faster speeds. For whatever reason, before I reached Evergreen, Alabama, I climbed up several thousand feet.

When it Gets Real

While in cruise at approximately 4000' altitude, I experienced a sudden and complete loss of power of N3748. One moment all was well, and the next moment, the propeller was fully stopped. My body told me that a restart was not possible due to the shaking experienced while it shut down. Perhaps I touched the starter; perhaps I checked fuel. I am not certain and I knew it didn't matter. The engine had failed.

I had been traveling over endless miles of forest, with low or non-existent options for emergency landings. I knew I had been playing my odds wrong (I'm always looking for emergency locations.)

This time, I looked straight down, and I realized that I was over the midpoint of the east-west runway of KGZH, Evergreen Regional Airport (AKA Middleton Field). Having already established glide, I made a left turn to reverse course and establish a dead-stick pattern downwind. I looked up the frequency for the airport, and quickly dialed into my radio.

I said: "Evergreen, are you there?"

An angel said back: "This is Evergreen Regional, I read you."

I said: "Evergreen, I am dead-stick overhead your airport now, landing. Can you observe my landing?" I don't remember using the emergency word, but I know that my language conveyed emergency, urgency, and fear, all in one.

The angel said: "Wilco, I'll hop in the truck and see you on the ground."

I think I got all that done while on downwind. A little voice in my hide was nagging me on the irony of dead-sticking into a huge paved airport, and then ending up short on final. That would be an insult wrapped in a tragedy inside of an emergency. I didn't want that to happen.

Adjusting glide, I added flaps and also added a little droop aileron. I listened to the electric linear motors driving the flaps and droop mechanism. I listened to the air flowing around the aircraft.

I turned base.

I turned final.

I passed over the threshold, probably 100+ feet off the ground.

I touched down. It was a pretty good landing. I was one-third down the runway, with a thousand feet behind me and two or three thousand ahead of me.

I rolled to a stop, and off to my right the Angel drove up in a pickup truck.

Tears / crying, but I was alive and unhurt.

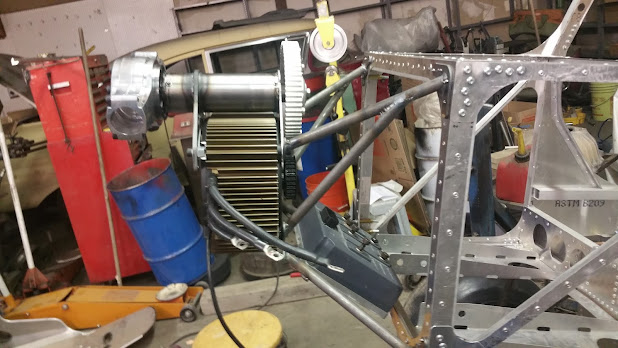

Engine Teardown

Let's cut straight to the cause: the engine failure was caused by a failure of and/or improper installation of a clip. The engine had clearly been operating for some time with the failed condition.

AftermathAfter the teardown, the plane was loaded into a rental truck, and I drove it home. It eventually was repaired and received a couple more upgrades, before I flew it to Alaska, and it was destroyed after another engine failure. (Another story for another time.)

Curious Questions

1) Why did the engine fail when I was mid-field over an airport?

2) Why did I upgrade the engine in the first place?

3) What could have been done to prevent this from happening?

The Angel

The airport manager was a wonderful woman, whose name was Terri. She was emotionally and resource-wise helpful to me and spared no effort to make my stay in Evergreen comfortable. I got the use of the airport car, of course. :-)