Please note: James' blog has moved to a Wordpress site. To access it, please visit

http://jameswiebe.wordpress.com/. All posts have been transferred to the new site, and all new posts will only be accessible via Wordpress. Thank you for your interest!

1. INTRODUCTION -- THE VIDEO

I've posted a video on youtube of a test flight of a Belite ultralight aircraft, with a strong running, reliable four stroke engine. The video is

HERE. Caveat: It's long, has some boring parts, and is filled with flying on a beautiful Kansas day.

The aircraft in the video is a Belite UltraCub, and it is available in kit form or fully assembled from Belite. When the tail turtledeck (fairing) is installed, it looks like a classic J3 cub. (Rummage through our

Belite website or

Belite UltraCub flickr photo site and you can find lots of photos of it with the turtledeck attached.)

You might want to watch the video if:

a) you are interested in flying on approximately 1.7 gallons gasoline per hour (91 octane or 100LL) without having to hassle with mixing oil

b) you'd enjoy purchasing a kit that starts at just $6995 (less engine) (until our current special expires).

c) you appreciate the value of a beautifully engineered aluminum airframe, comparable in many respects to kits and factory assembled aircraft costing ... a LOT more.

d) You'd like to fly without FAA registration, without medical, without a pilot's license (but with pilot skills) appeals to you. This airplane will do it, with a flying weight of 278 pounds (including parachute). (That's the maximum allowed under FAR Part 103). (Weights vary by option; this is with heavy spars and ribs; so you can do better)

e) You'd like to fly with an engine that's been proven in aircraft use for many years, weighs 88 pounds, has dual ignition, and develops 45 HP, and can be built from a kit, or purchased fully assembled, or scratch built from VW parts.

f) The idea of flying a small aircraft that has well mannered controls appeals to you -- it can be flown without feet on the rudder pedals (and I'll be posting a video showing that sometime very soon).

2. THE GORGEOUS ALUMINUM CABIN which forms the foundation of our product

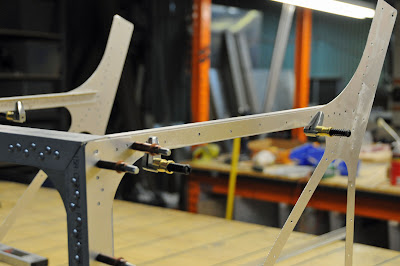

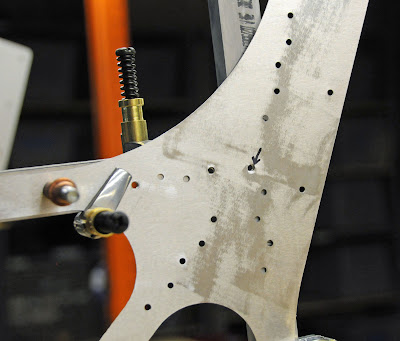

Here's are pictures of the aluminum fuselage cabin in our UltraCub, constructed from a variety of aluminum, including aerospace 7075; 2024; and 6061T6:

|

| Quartering rear view of the Belite Ultralight Airplane (UltraCub) cabin |

|

| Top Sunroof aluminum skin -- that's 7075T6 aluminum! |

|

| View of the inside of the cabin. Divider panels are for small baggage compartments. |

|

| Bottom of the fuselage cabin. Box beams. Phenomenal strength. |

|

| Kansas sunlight, a cabin, and shadows. |

When you order our kits, all of the cabin panel skins and gussets come CNC cut and are 99.95% predrilled. Everything matches up. You are responsible for cutting the aluminum tubes and matching them to the skins, then riveting. Since every single dimensional corner in the cabin has a matching premachined, predrilled gusset, we've made it hard to screw up. Jigs are irrelevant.

3. WHAT DID I DO ON TODAY'S FLIGHT?

Here's what I did on today's test flight:

a) takeoffs

b) landings

c) investigation of aileron / flaperon authority

d) elevator control

e) stalls (couldn't really get it to stall)

f) approach speeds

g) fuel flow analysis (burned about 1.7 gallons in 1 hour -- will be working on refining this number) (should be good for 3 hours of cruise flight)

h) steep turns

i) climbs

j) power off descent

k) brief formation flight with a RANS SII Coyote -- thanks Mike :-)

l) waved my hand out the cockpit at the camera

Most of this made it onto the video, but not all. Please watch for me waving my hand out of the cockpit.

4. WHAT HAVE I LEARNED ABOUT THE ULTRACUB?

Some very interesting points to consider:

a) it turns without using the rudder pedals. (It's not such a 'rudder airplane' as prior Belite aircraft.)

b) The ground run is short and it climbs like crazy

c) it sounds cool -- very nice airport wow factor

d) the engine still isn't developing anywhere near full power. We've got it turning 3125 RPM with our selected prop, yet max power is available at 3600 RPM, should we choose to re-pitch the prop. But why? the airplane is probably flying at Part 103 max speed, as is. TBD.

e) it is the most fun I've had flying a Belite.

f) it has several baggage and map compartments (you can see them in the cabin photos)

g) the riveted aluminum structure is easier to check and repair (welded aluminum requires much more vigilance against cracking in the welds.

5. WHAT SECRET DESIGN FEATURES DOES IT HAVE?

a) The Burgundy ultracub is an ultralight airplane, flying under part 103. Getting weight down was a real problem, because the cabin in the Burgundy plane had a lot of goofs, requiring the use of extra metal to fix. I was determined to meet weight requirements, so I used a hand toss parachute with a weight of 7.5 pounds (not yet installed, but it showed up and will be installed very soon). (Max weight with parachute is 278 pounds; if we put it on floats, max weight is 338 pounds). I also calculated weight with just one quart of oil, although the engine is flying on two quarts. It has a few other weight saving tricks, which will remain secret for now. Such as titanium axles, a composite tailspring, thinner polycarbonate windshield, and smaller wheels.

b) After the flight test sequence is completed, the cabin in the Burgundy plane will be replaced with a new cab, just like the photos above. This will cut the weight some more, and allow me to reclaim my titanium axles.

c) I was determined to make weight with brakes and steel springs, because most people want them. But if you don't, the plane is even lighter.

d) The engine mount is radically small and light.

e) The flaperons are full span. This increased wing area, decreased stall, and probably aided the snappy turn characteristics which this plane has. This is our first aircraft with full span flaperons. They have 4 attachment points per wing. All older Belite flaperons had 3.

f) The wings are plain old aluminum spars + baltic birch plywood ribs. Inexpensive. Switching to carbon fiber spars and aluminum ribs would save even more weight.

g) The wingspan was enhanced by about 4 inches, by widening the cabin wing attach points. This increased effective lift as well, and also makes the wings easier to fold.

h) The earlier version of this plane had winglets. They've been deleted.

i) The wing area is now around 112 square feet.

j) Although we are hand-propping the engine, you could use an electric starter, but it would cost a lot of weight. You'd have to register experimental, or buy all the weight saving options (carbon fiber spars) in order to legally comply with Part 103 weight requirements. The engine is easy to start.

6. WHAT ABOUT THAT ENGINE?

|

| 1/2VW on Belite Ultralight Aircraft |

Well, it's a 1/2VW with dual ignition, and they've been around for years. We hadn't tried one because we couldn't get the weight of our plane down enough, but with our new aluminum cabin design, we can finally do it without resorting to exotic materials such as carbon fiber spars.

It comes from Scott Casler at

Hummel Engines, and it is a very impressive product. We bought the top of the line with 45HP and Nicosil cylinders, but a lower HP solution will work fine.

You can also get kits for a very similar engine from

Great Plains Aircraft, or you can make one yourself from readily available plans.

Our engine mount is totally custom, and the magneto sticks into the top of the front cabin. We'll accomodate this with a hole in the firewall.

7. WHERE TO NOW?

I'll be traveling on business for much of the next two weeks, but I've already taken many photos of the cabin production procedure, and I plan to get that posted.

The airplane is running so well, flying so nicely, that I'm hoping (weather permitting) to take it on a nice cross-country flight sometime in December.

I'm eager to fly it again.

|

| Ultralight Airplane with 4 Stroke Engine -- Takeoff! |