Please note: James' blog has moved to a Wordpress site. To access it, please visit

http://jameswiebe.wordpress.com/. All posts have been transferred to the new site, and all new posts will only be accessible via Wordpress. Thank you for your interest!

Some of you know that my background is small town Mennonite (Hillsboro, KS), and a few of know that my mother is Katie Funk Wiebe, a retired but still prolific Mennonite author. Mom writes her own blog,

Second Thoughts, and I like to think that I got a good measure of her writing DNA. I think the book count she's authored currently stands around 20ish. And she's not done yet!

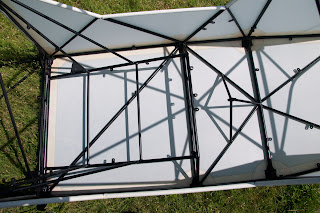

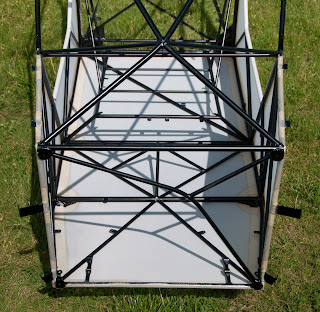

While having lunch with her a couple of days ago, she let me look through an excellent book on Mennonites, and was kinda stunned to see a 1907 photograph of some Russian Mennonites, standing next to a Wright-esque airplane (glider) they had constructed. I have copied only a fuzzy photo, and leave it to you to surf to other websites which contain old historical information on this impressive Mennonite / Aviation accomplishment.

Imagine you are in Russia, 105 years ago, and you see this:

Wow. !!

It seems this is the HUP airplane project at Chortitza, with HUP standing for Hildebrand, Unruh, and Plenert.

Excerpting from an online article, found at http://www.mennonitehistorian.ca

...Launching a glider on the flat Russian steppes was as great a feat as designing and building one. The youths solved this by fitting HUP with skis to slide on grass and using two horses for launching power. A powerful stallion provided initial horsepower to overcome inertia and was then cut loose. An exceptionally fast mare continued at a dead gallop towing the machine sufficiently high into the air to glide blissfully around until speed loss and lift forced the pilot to land.

...The HUP Project at The boys' efforts didn't always meet with approval in an agriculturally-oriented community with strict religious standards where the "man with wings" philosophy also predominated. Nonetheless, their efforts invariably drew a crowd. Sometimes the young gliders capitalized on this by charging admission and occasionally an adult donated to the project.

...By 1907 the men, aged 17 to 20, felt they had sufficient experience, knowledge and finances to try building a real plane. They abandoned the glider and set to work designing and building HUP II. They planned and built the fourThe cost was so high that they couldn't afford wheels and once again had to rely on

skis....

You can read one of articles

here.